LLNL is committed to the highest level of performance in the areas of environment, safety, and health (ES&H) and security. Best practices are implemented throughout the Laboratory, and management systems provide for continuous improvement. The safety of employees and the public is ensured through prudent risk management coupled with active measures to prevent accidents.

Effective Environment, Safety, and Health

In 2013, the National Safety Council presented the Laboratory with a Significant Improvement Award for strong and improving safety performance. Key safety performance statistics are at a multidecade low. The FY2013 total recordable case (TRC) rate of 1.4 continues the prior year’s excellent performance and represents a 25 percent decrease from 2011. More significantly, the days away, restricted, or transferred (DART) rate, which is a measure of severity of injuries, continues to improve (to 0.51) and is down by more than 50 percent over two years.

Inspections and assessments of worker safety and health programs demonstrated a high level of performance in key areas, with no major deficiencies. Continuous safety improvements include initiatives to implement additional injury and illness preventive measures, improve work control documentation, and streamline ES&H training (which has saved nearly $400,000 to date).

New robotic systems were deployed in FY2013 to meet emerging needs for operational safety. A remote-controlled robot dubbed D2T3 (in honor of the fusion fuel isotopes deuterium and tritium) is now checking the beta and gamma radiation levels in the NIF target bay after high-neutron-yield experiments. LEXI (for Livermore Explosives iRobot) is at work in the firing tanks at the High Explosives Applications Facility.

Laboratory employees’ focus on safe work practices is supported by high-quality, well-documented safety management programs. LLNL’s Integrated Safety Management System holds Occupational Health and Safety Assessment Series (OHSAS) 18001 accreditation. LLNL also received International Organization for Standardization (ISO) 9001 accreditation for its Quality Management System (see Management and Operations ). In addition, the Laboratory’s Environmental Management System, which earned triennial recertification under ISO 14001, provides a systematic approach to identifying and reducing the environmental impact of Laboratory activities with strong focus on continuous improvement. In FY2013, LLNL operations at the main site and Site 300 near Tracy, California, were compliant with regulations and had no adverse impact to public health or local environment.

Award-Winning Sustainability Efforts

LLNL is enhancing the sustainability of site operations through heightened employee awareness, continual improvements to existing infrastructure, and collaborations with expanding research programs in renewable energy generation and energy efficiency. The steps taken in 2013 include replacing older boilers in buildings with high-efficiency models, rebuilding several chillers, and installing advanced metering to monitor electricity and natural gas usage. In addition, the Laboratory is undertaking sustainability demonstration projects and implementing award-winning sustainability improvements.

Two projects were recognized by NNSA with 2013 “Best in Class” Sustainability Awards, and a third project on sustainable landscaping was also honored. A “Best in Class” award went to the NIF team for its “active risk management” approach to reducing low-level radiological waste generation and preventing pollution. The team’s effort has resulted in a reduction of an estimated 12,240 cubic feet of radiological waste per year, $1.3 million in consumables, and 40,000 person-hours per year of time spent managing NIF hazards.

The second “Best in Class” award was earned for LLNL’s holistic waste reduction program, which builds upon a well-established recycling program that diverts more than 68 percent of the Laboratory’s municipal waste from landfill. Recent efforts focused on expanding the types of items recycled and promoting a culture that considers reuse first. To date, an estimated $524,000 has been saved through reuse activities, and more than 30,000 pounds of items for which a recycling pathway was not previously available were recycled. An internal “Craigslist” application has been developed to facilitate reuse exchanges sitewide and better manage reuse of property.

Site Security Changes Successfully Implemented

LLNL efficiently and effectively maintained secure operations in FY2013. The Laboratory’s Security Organization conducted a strong self-assessment program and met all milestones on or ahead of schedule and within budget and completed a number of security enhancements. Major changes in LLNL’s security posture were effectively implemented as the Laboratory transitioned to Security Category (CAT) III operations. Special nuclear material items that require the highest level of protections were removed from the site by September 2012—a year ahead of the schedule originally developed. Implementation of a compliant and effective CAT III security program, including changes to physical protection systems and staffing levels, reduced Laboratory security costs by approximately $40 million per year.

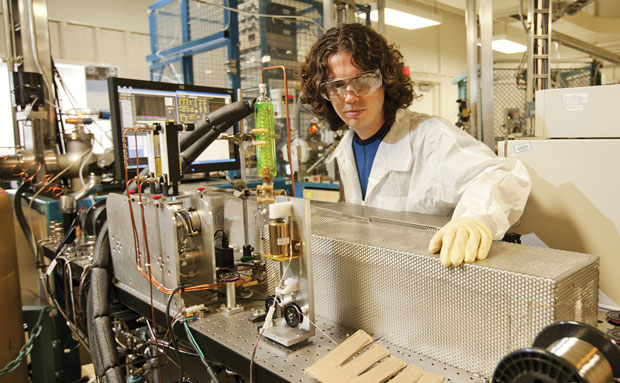

Safety Self-Assessment for DOE

In 2013, LLNL completed DOE’s Safety Conscious Work Environment (SCWE) Self-Assessment, which included extensive document reviews, participation by more than 3,200 employees in a safety culture survey, and 258 personal interviews. Self-assessment results affirmed that LLNL programs and procedures support a positive safety culture, workers believe management values safety, and employees feel free to raise concerns and are empowered to stop or pause work as appropriate. Avi Thomas is shown working safely with a biological accelerator mass spectrometry instrument.