Ensuring national security with a modernized nuclear weapons stockpile and a responsive nuclear security enterprise

LLNL’s foremost responsibility is strategic deterrence. The Laboratory is sustaining weapons systems in the nation’s nuclear arsenal as it engages in programs and partnerships that jointly modernize the stockpile and weapons production enterprise. Effective deterrence relies not only on the nation’s deployed weapons systems, but also on the extensive science and technology capabilities of its national security laboratories and the agility of the nuclear security enterprise (NSE) to respond to emerging national needs.

Annual Stockpile Assessment

In FY 2023, LLNL completed Cycle 28 of the annual stockpile assessment. The process included a formal comprehensive peer review between LLNL and Los Alamos National Laboratory (LANL) of each other’s weapons systems. Laboratory experiments and application of enhanced physics and engineering simulation codes provide the technical foundation for evaluating the safety, security, and effectiveness of weapons. These activities enabled an assessment of the condition and sustainment of the B83, W80-1, and W87-0 stockpile systems. LLNL also completed a significant upgrade to capabilities at the Pantex Plant for gathering surveillance data.

W80-4 Life Extension Program (LEP)

LLNL is the design agency partnering with Sandia National Laboratories (SNL), production agencies, and the U.S. Air Force to develop and certify the W80-4 warhead for the bomber-delivered Long-Range Standoff (LRSO) missile. While challenges remain, the team is making excellent progress in the LEP. Programmatic work included executing design reviews, completing multiple high-fidelity engineering tests, efforts improving product producibility, and supporting U.S. Air Force LRSO flight-test activities. In November 2022, the development team successfully completed a critical mid-program review with the Department of Defense (DOD), showing that the warhead baseline design complies with DOD requirements and would perform as expected after surviving flight environments. This key milestone and the System Baseline Design Review prepared the LEP for transition to Phase 6.4 (production engineering) in May 2023.

Production engineering builds on the initial design phases by fully engaging partnerships across the NSE. LLNL’s partnership with the Kansas City National Security Campus (KCNSC) has enabled improvements to the acceptance rate of key components needed for system delivery. LLNL has worked with LANL and SNL to integrate complex schedules and ensure that efforts focus on the key technical challenges. The partnership with Pantex has been essential to addressing challenges in the supply chain and production of insensitive high explosives (IHE), as well as preparing for assembly and delivery of systems.

The W80-4 will reuse existing designs and components while incorporating modern components and safety features. The LEP is taking advantage of new manufacturing methods that minimize costs, increase throughput, and reduce the need for environmentally sensitive materials and processes. The first production unit of the W80-4 is scheduled for September 2027.

W87-1 Modification (Mod) Program

LLNL is the design agency partnering with NNSA laboratories, plants, and sites to deliver a warhead to replace the aging W78. To be deployed on the U.S. Air Force’s Sentinel ballistic missile (under development) in the early 2030s, the W87-1 will be the first modern warhead that is 100 percent newly manufactured. In FY 2023, the W87-1 Mod Program successfully moved to Phase 6.3 (engineering development). Technical activities are focused on maturing weapon design options and modern manufacturing methods. The program is pursuing innovative, transformational partnerships across the NSE to introduce new materials, manufacturing techniques, and processes to meet W87-1 and future stockpile systems requirements. Advances in the tools of science-based stockpile stewardship, including acquisition of El Capitan and the recent successes at the National Ignition Facility, enable confident certification of the new warhead without nuclear explosive testing.

Enclaves and Production Partnerships

Success in the modernization programs depends on forging an integrated effort among the design agencies and production agencies within the NSE and strong partnerships with the U.S. Air Force and their contractors. LLNL is spearheading expanded collaborations to develop innovative materials and manufacturing techniques. Researchers from the Laboratory and KCNSC work side-by-side at the Polymer Enclave at LLNL using machines, tools, and other production equipment that are equivalent (and in some cases, identical) to resources at KCNSC. They are partnering to meet rate production goals needed for the modernization programs, and are co-developing, with other stakeholders, technological advances in additive manufacturing. In addition, LLNL and the Y-12 National Security Complex have teamed up to rapidly modernize technology and production methods for crucial weapons components.

LLNL has also established the Energetic Materials Development Enclave Campus (EMDEC) as a manufacturing partnership within the NSE. It leverages the extensive suite of capabilities at the Laboratory with the goal of reducing the time to achieve high-yield-rate production. The collaboration also serves as a test bed for next-generation approaches to energetic materials. EMDEC features the Facility for Advanced Manufacturing of Energetics (FAME), where first-of-their- kind technologies have been developed and implemented to safely 3D-print IHE.

Preparing for Exascale

Delivery of El Capitan, with a peak performance to exceed 2 exaflops (quintillion calculations per second), is expected to be completed in early 2024, with the goal to deploy it for classified use in late FY 2024. More than a factor of 15 improvement over NNSA’s current largest supercomputer, El Capitan will be used by NNSA scientists to support stockpile modernization and meet other high-priority national security needs. The machine enables researchers to run ensembles of high-fidelity 3D multiphysics simulations to quantify uncertainties. El Capitan features accelerated processing unit chips with expanded memory and high processing speed together with an advanced interconnection network for large simulations that require many nodes. Building and preparing for El Capitan has been a multiyear effort that has benefited from many contributors and a strong partnership between the Laboratory and system vendors (see Partnerships). In addition to the $100-million upgrade to the Livermore Computing facility, LLNL is preparing the operating and data storage systems and readying applications for efficient use on El Capitan. Much of the software ecosystem for the machine has been developed through DOE’s Exascale Computing Project.

Nuclear Survivability Experiments

The National Ignition Facility (NIF) provides unique experimental capabilities for assuring that the nation’s nuclear weapons and other critical military systems would survive and function under hostile conditions in a nuclear conflict.

NIF performs an average of 40 to 50 shots per year as part of its National Security Applications program, which supports researchers across the defense community. The experiments provide x-ray, neutron, and electromagnetic pulse environments for vulnerability and hardness testing of electronics, weapons parts, and materials. Data collected during shots are used to qualify components and validate codes designed to determine the effects on systems.

Achievement of fusion ignition at NIF is very important to the success of many facets of stockpile stewardship (see National Ignition Facility). For nuclear survivability, it greatly enhances capabilities to test components and materials by exposing them to an intense dose of neutrons. The December 2022 shot not only achieved ignition, it tested new experimental hardware designed to survive megajoule exposures. The cryogenic-compatible x-ray, neutron, and blast snout (CryoXNBS) demonstrated the capability to test samples, materials, or diagnostics in megajoule environments.

Flight Dynamics and Hypersonics

LLNL engineers have developed an advanced flight simulation package, Sora, as a new capability for use in the national security community. Historically, LLNL modeled the thermal–structural response of warheads to the extreme loads and conditions of re-entry based on data from DOD contractors’ codes that simulate the flight dynamics of the delivery vehicle. Sora simulates the flight vehicle and nuclear warhead in a complex multiphysics, multiscale environment that includes hypersonic air chemistry, ablation, heat transfer, structural dynamics, weather, and cloud microphysics. Use of a combined model will streamline development of new systems, saving time, reducing costs, and leading to designs that better optimize performance. Collaboration with academic partners and the U.S. Air Force and Army laboratories has been crucial to the development of Sora. Efforts are underway to expand the user base.

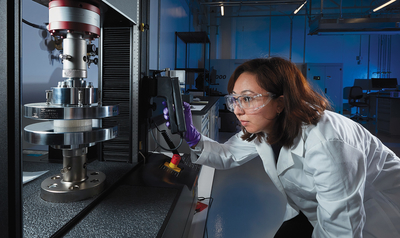

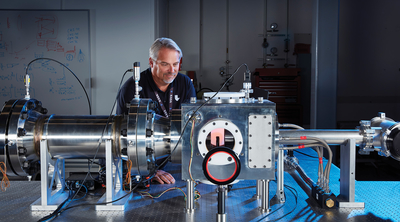

Laboratory researchers are also bringing into operations the Energy–Matter Interaction Tunnel (EMIT) to assess the resilience of materials under the extreme conditions of hypersonic flight. EMIT meets the challenge of creating a test environment with both well-characterized turbulent air flow and high-temperature material, heated by a laser source outside the experimental chamber. A suite of diagnostics characterizes the mechanical and chemical response of a material coupon. The ability to conduct frequent tests—coupled with LLNL’s outstanding capabilities to develop novel materials and simulate material behavior in extreme conditions—will help advance hypersonic research. Development of EMIT would not have been possible without extensive collaboration with many institutions engaged in hypersonic research, who will also be users of the facility.

Pulsed Power for Scorpius

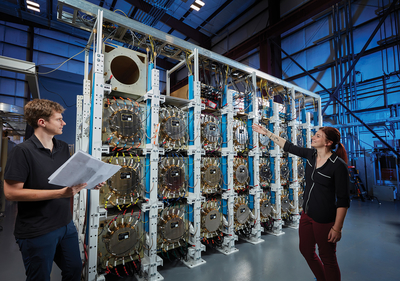

NNSA laboratories and sites are building the Scorpius accelerator in a tunnel 1,000 feet underground at the Nevada National Security Site. LLNL delivered on a major milestone in FY 2023 in support of the project. The football field–length machine will be NNSA’s next-generation electron beam accelerator to diagnose subcritical experiments that compress plutonium to high density with high explosives. In these contained experiments, short bursts of x rays will take radiographic images of the material, which will be used to validate simulation codes and assess the effects of aging and manufacturing methods on weapon performance. LLNL’s responsibility is to develop and deliver a solid-state pulsed power system for Scorpius. Circuit boards in 984 line replacement units (LRUs), rather than massive banks of capacitors, will power the linear accelerator. Each LRU includes 45 printed circuit boards, totaling 3.5 million electrical components in the pulsed power system. After extensive assembly and testing, the first cluster of 24 LRUs was demonstrated to meet requirements in September 2023.

Exploring Energetic Materials

In experiments and simulation, LLNL is at the frontiers of energetic materials research. In FY 2023, LLNL researchers designed a main charge that utilizes RX-72, a candidate IHE that has compelling performance properties. The team was challenged to make systems-level trade-offs in developing the new explosive, which provided staff critical training and career development opportunities. The effort culminated in the successful delivery of main charge components for integrated testing and the transfer of manufacturing technology to partners at the Pantex Plant. In other research efforts, computer simulations performed with collaborators demonstrated that crystal structure prediction is a useful tool for examining various ways the molecules can pack together in energetic materials. The method used is a physics-based approach that works by randomly generating crystal structures, optimizing them, and ranking the resultant structures by their predicted stability. It successfully predicts the crystal structure of commonly used energetic materials.