Conducting safe, secure, and environmentally sound operations and modernizing the Laboratory’s infrastructure to meet evolving mission needs

LLNL is committed to the highest level of operational performance. The Laboratory implements best practices in environment, safety, and health (ES&H), and security. Management systems support continuous improvement in work practices and target investments to modernize the Laboratory’s infrastructure. Prudent risk management, coupled with active measures to prevent accidents, ensures the safety of employees and the public.

Effective ES&H and Work Planning

The Laboratory’s injury and illness statistics continue their long-term downward trend. FY 2015’s total recordable case (TRC) rate of 0.95 continues the prior year’s excellent performance and represents about a 60-percent decrease since the contract transition in 2008. Similarly, the days away, restricted, or transferred (DART) rate, which is a measure of the severity of injuries, is down by about 60 percent over the same time period. To prevent injuries, the Laboratory continually emphasizes attention to safety and undertakes concerted efforts to improve performance in high-risk areas, including facilities and infrastructure (F&I) operations and protective services.

Continual improvement is a key facet of LLNL’s Integrated Safety Management System, which is certified with Occupational Health and Safety Series (OHSAS) 18001 accreditation. One major effort nearing completion is the Laboratory’s project to revamp work planning and control (WP&C) in response to incident assessment recommendations and worker feedback. Designing the new WP&C processes, controls, and implementation concepts was an extensive effort that included gathering best practices from around the Laboratory and across the NNSA complex. A beta pilot of the new WP&C process, tested in selected areas of the Laboratory, has been judged successful. The Laboratory has extended the WP&C pilot process through FY 2016 before institution-wide implementation.

Progress Toward Site Sustainability Goals

Ecologically responsible work practices are ensured by LLNL’s Environmental Management System, which has International Organization for Standardization (ISO) 14001 accreditation. These practices provide a systematic approach to identifying and reducing the impact of Laboratory activities. The 2014 Site Annual Environmental Report (issued in October 2015) records LLNL’s compliance with environmental standards, describes protection and remediation programs, and presents the results of environmental monitoring. A notable success in 2015 was achieving cleanup standards for tritium in contaminated areas of Site 300.

LLNL exceeded several of its FY 2015 sustainability goals and is making progress toward meeting ambitious FY 2020 goals. The Laboratory has already achieved its FY 2020 greenhouse-gas-reduction goal of 28 percent and is on target to meet the water intensity reduction goal. A 3.3-megawatt solar photovoltaic system at the Livermore site, which began construction in late 2015, will contribute to meeting the renewable energy use goal.

Livermore earned an NNSA Sustainability Award for its novel water conservation plans. The multifaceted approach to cutting water usage in drought-stricken California ranges from replacing turf with water-wise landscaping and fixing leaky pipes, to using treated water—cleaned with a reverse osmosis unit—rather than potable water in cooling towers. LLNL also received a DOE Sustainability Award for a multiyear effort to consolidate 26 data centers into one Enterprise Data Center, which conserves energy and reduces costs. The center houses more than 2,500 mission-critical science, engineering, computational research, and business computing systems.

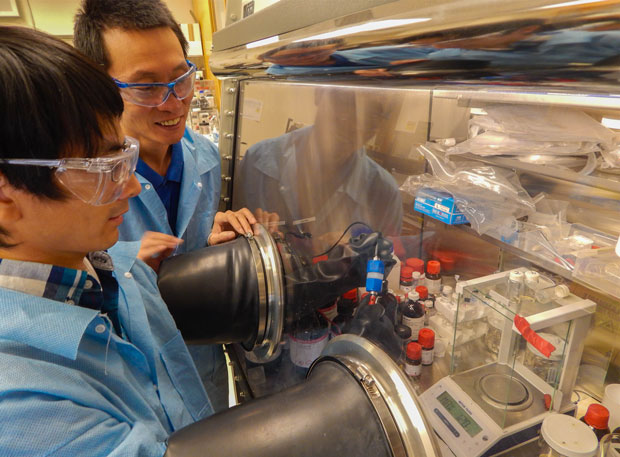

Effective Operations

In FY 2015, operations at LLNL were effectively and efficiently managed in all principal areas: ES&H, security, business operations and systems, and legal management. Of particular note is an initiative to improve F&I maintenance by deploying dedicated F&I teams. The teams’ in-place workers are gaining greater familiarity with program operations and specialized equipment and can resolve more difficult problems. They receive direct feedback from the programs on how their efforts are helping mission success. LLNL also received better-than-goal Facility Condition Index scores; was recognized as the one NNSA site with “excellent performance” in the DOE 2014 Annual Criticality Safety Report to the Defense Nuclear Facilities Safety Board; and made improvements that enhance and bring substantial cost-benefit to security operations.

Revolutionizing Infrastructure Management

LLNL is working with NNSA headquarters as an innovative partner to help revolutionize F&I management across the NNSA complex. NNSA is working toward a comprehensive approach that considers investments in capital equipment, facilities maintenance, and new construction, and weighs risks to successful mission execution. Currently, the Laboratory is benefiting from flagship projects funded by the NNSA Capability-Based Infrastructure Program—targeted at crucially needed capital equipment. Broader future Laboratory needs are detailed in the LLNL Ten-Year Site Plan, identified as “best in the complex” in 2015. NNSA will pilot an improved, more comprehensive site planning process with LLNL next year.

NNSA enterprise risk management entails effectively targeting investments by weighing facility condition against consequence to mission resulting from potential failure. Livermore is serving as NNSA’s Center of Excellence for implementing BUILDER, a knowledge-based condition-assessment infrastructure modeling system. LLNL is also the pilot site for implementing the Mission Dependency Index (MDI), a tool for assessing the mission consequences of F&I failure.

Celebrating 60 Years of Site 300 Stewardship

Sixty years ago, the University of California Radiation Laboratory began testing high explosives at what would become known as Site 300. It is home to the Contained Firing Facility, the largest indoor explosive-testing facility in the world, the newly refurbished Engineering and Environmental Test facility, and other mission-supporting facilities. Activities at Site 300—crucial for the success of stockpile stewardship—are performed safely with attention to protecting the remote, rugged area’s fragile ecosystem. Designated as a critical habitat, the area is home to coyotes, deer, bobcats, golden eagles, red-tailed hawks, and many threatened or endangered species.